Complete solutions in metalwork, providing superior products and engineering for over 30 years

2025 Completed Projects

Throughout 2025, MK Metals Ltd successfully delivered a diverse range of projects across the residential, education, commercial, and specialist sectors. Each completed scheme reflects our commitment to precision engineering, quality-controlled fabrication, and reliable on-site delivery.

From complex architectural metalwork packages to technically demanding refurbishments and residential developments, our 2025 projects demonstrate our ability to meet high design standards, regulatory requirements, and programme expectations. We are proud to have worked collaboratively with developers, architects, and contractors to deliver durable, compliant, and well-integrated metalwork solutions across the UK.

Explore a selection of our completed 2025 projects below.

🏘 Client: Optivo Homes (now Southenr Housing)

🏛 Architect: TP Bennett

📍 Location: Bermondsey, London

📄 Contract: JCT Design and Build Contract 2016

💷 Project Value: £180,000

📅 Completion: Q1 2025

Project Summary: Residential Conversion – Architectural & Structural Metalwork

MK Metals Ltd were appointed under a JCT Design and Build Contract to deliver a complex architectural and structural metalwork package as part of the conversion of Argo House from a commercial building into a residential development.

The scheme comprised one-, two-, and three-bedroom apartments with private balconies and decking, together with shared commercial and residential circulation areas.

The project required significant coordination, detailed architectural input, and compliance-driven fabrication across multiple stair cores and blocks.

Scope of Works

-

Design, architectural detailing, GA drawings, and structural engineering coordination for all items within the metalwork package

-

Design, fabrication, supply, and installation of commercial staircases, handrails, and balustrades across multiple stair cores

-

Design and installation of mesh stair treads, including perforated atrium treads eliminating the requirement for screed infill

-

Design, fabrication, and installation of atrium staircases and perimeter balustrading across multiple levels

-

Fully designed and powder-coated balustrades, handrails, and stair components to feature and circulation areas

-

Design, fabrication, and installation of wall-mounted handrails to residential stair cores

-

Design and installation of external and roof-level railing infills and handrails to blocks and linkways

-

Structural steel remedial works, including design responsibility, removal and replacement of existing beams in accordance with the structural engineer’s report

-

Design, fabrication, and installation of bin store security fencing and roller shutter door steelwork

-

Design and installation of perimeter and elevation handrails, together with associated remedial roof metalwork works

Materials & Finishes

-

Structural steelwork fabricated from certified steel grades, with protection systems specified in accordance with BS EN ISO 12944 to suit internal and external exposure conditions

-

Balustrades and handrails manufactured in steel and designed to meet BS 6180 requirements for guarding and fall protection

-

Mesh stair treads, including perforated atrium treads, fabricated to eliminate screed infill and support visual permeability

-

Glass infills incorporated where required, using toughened or laminated safety glass in compliance with BS EN 12150 and BS EN 14449

-

Powder-coated finishes applied to staircases, balustrades, and handrails for a high-quality architectural appearance and durability

-

Red / grey oxide primer and galvanised paint finishes applied where specified for phased installation and remedial steelwork

-

All materials and finishes were coordinated with architectural intent, GA drawings, and structural engineering requirements to ensure compliance, performance, and long-term durability.

Standards & Compliance

All works were designed, engineered, fabricated, and installed in accordance with relevant British Standards, statutory requirements, and approved project documentation, including:

-

BS EN 1090 – Execution of steel structures, with full material certification and traceability

-

UKCA compliance for all applicable structural steel components

-

BS 6180 – Barriers and guarding to staircases, balconies, and circulation areas

-

Building Regulations, including Approved Documents A, B, K, and M

-

BS EN ISO 12944 – Corrosion protection systems for steelwork

-

Glazing standards, including BS EN 12150 (toughened glass) and BS EN 14449 (laminated glass)

All works were coordinated with architectural GA drawings, structural engineering design, and building control requirements to ensure safety, compliance, and long-term performance.

Project Outcome

Completed in Q1 2025, Argo House demonstrates MKMetals Ltd’s ability to deliver technically complex, compliance-driven architectural and structural metalwork packages within challenging refurbishment environments, under a JCT Design and Build framework.

🏘 Client: Private Coastal Holiday Park Operator

🏛 Architect: N/A

📍 Location: South East England

📄 Contract: Purchase Order

💷 Project Value: £89,000

📅 Completion: Q2 2025

Project Summary: Coastal Holiday Park – Architectural Metal Railings

MKMetals Ltd were appointed to design, fabricate, and install architectural metal railing systems across a coastal holiday park, supporting the enhancement of external areas surrounding park homes, lodges, and communal access routes.

Set within a coastal environment, the project required metalwork solutions capable of withstanding harsh weather conditions, salt-laden air, and increased corrosion risk, while maintaining an attractive appearance appropriate for a leisure and holiday setting. The railings provide essential edge protection to decking areas, steps, ramps, and walkways used daily by guests and maintenance teams.

Scope of Works

-

Design, fabrication, supply, and installation of architectural metal railings

-

Railings installed to park home decking, access stairs, ramps, and circulation walkways

-

Guarding provided to level changes and exposed edges across private and communal areas

-

Coordination with existing decking systems and holiday park infrastructure

-

Installation programmed to minimise disruption to guests and park operations

Materials & Finishes

-

Steel railing systems designed specifically for coastal exposure conditions

-

Corrosion protection systems specified in accordance with BS EN ISO 12944, suitable for marine and coastal environments

-

Finishes selected to deliver durability, low maintenance, and long-term visual consistency

-

Materials chosen to complement the appearance of park homes and the surrounding coastal landscape

Standards & Compliance

All railing systems were designed, fabricated, and installed in accordance with relevant British Standards and statutory requirements, including:

-

BS 6180 – Barriers and guarding

-

UK Building Regulations, including Approved Document K

-

Protective coatings and finishes applied to suit coastal exposure and service life requirements

-

Installation undertaken to ensure safety, durability, and compliance within a leisure environment

Project Outcome

The completed railings enhance guest safety while contributing to the overall quality and appearance of the holiday park. The project demonstrates MK Metals Ltd’s expertise in delivering robust, compliant metalwork solutions tailored to the demands of coastal holiday and leisure environments.

🏘 Client: Donnington Grove Golf Course

🏛 Architect: N/A

📍 Location: Donnington, Berkshire

📄 Contract: Purchase Order

💷 Project Value: £50,000

📅 Completion: Q2 2025

Project Summary: Estate Walkways, Bridge Structure & Handrails

A valued returning client appointed MKMetals Ltd to replace existing timber walkways, the main bridge structure, and associated handrails at the historic Donnington Grove Estate.

Set within approximately 500 acres of Berkshire countryside, the estate is defined by parkland, woodland, landscaped gardens, and historic views toward Donnington Castle. The upgraded walkways and bridge form a vital part of the estate’s pedestrian routes, requiring solutions that enhance safety and durability while remaining visually sympathetic to the rural and heritage setting.

Scope of Works

-

Careful removal of existing timber walkways and bridge elements

-

Design, fabrication, and installation of new structural walkways

-

Replacement of the main bridge structure within a sensitive landscape setting

-

Supply and installation of compliant handrails to walkways and bridge edges

-

Coordination with existing trails, ground conditions, and surrounding landscaping

-

Installation works undertaken to minimise disruption to the estate and its natural environment

Materials & Finishes

-

Structural steelwork designed for long-term external and rural exposure

-

Corrosion protection specified to suit countryside conditions, reducing ongoing maintenance

-

Durable, pedestrian-friendly non-slip decking surfaces

-

Handrails finished to provide safety, longevity, and a restrained visual presence

-

Materials selected to complement the historic and natural character of the estate

Protected Waterways & Environmental Considerations

The replacement walkways and bridge cross and interface with protected waterways running through the Donnington Grove Estate. As a result, all works were carefully planned and executed with a strong emphasis on environmental protection and ecological sensitivity.

Construction activities were coordinated to prevent contamination, disturbance, or obstruction of the watercourses, with installation methodologies selected to minimise interaction with the water environment. Material selection and corrosion protection systems were also carefully considered to ensure long-term durability without adverse impact on surrounding habitats.

By adopting a considerate and controlled approach to working near protected waterways, MK Metals Ltd ensured the works were delivered responsibly, preserving the ecological integrity of the estate while improving access and safety for users.

Standards & Compliance

All works were designed, fabricated, and installed in accordance with relevant British Standards, statutory requirements, and best-practice guidance for heritage, countryside, and environmentally sensitive environments, including:

-

BS EN 1090 – Execution of steel structures

-

UKCA compliance with full material traceability

-

BS 6180 – Barriers and guarding

-

BS EN ISO 12944 – Corrosion protection systems for steelwork

-

Compliance with applicable UK Building Regulations

-

Works delivered with due regard to environmental protection and conservation requirements

All elements were delivered in close coordination with the client to ensure safety, longevity, environmental responsibility, and alignment with the heritage value of the Donnington Grove Estate.

🏘 Client: Private Residential Client

🏛 Architect: N/A

📍 Location: Winchester, Hampshire

📄 Contract: Direct Appointment

💷 Project Value: £110,000

📅 Completion: Q3 2025

Project Summary: Private Residential – Structural Steelwork

MK Metals Ltd were appointed to deliver the full structural steelwork package for a high-quality new build private residential property in Winchester. The steelwork formed a critical part of the building structure, enabling the architectural layout, open-plan living spaces, and integration with modern construction methods.

Working directly with the client and wider project team, MK Metals Ltd provided a coordinated and technically robust solution, ensuring the steelwork supported both the structural performance and design intent of the property.

Scope of Works

-

Design development and structural steelwork coordination

-

Fabrication, supply, and installation of primary and secondary structural steelwork

-

Steel beams and supporting elements for open-plan internal layouts

-

Coordination with foundations, masonry, and follow-on trades

-

Installation carried out within a residential construction environment

Materials & Finishes

-

Structural steel fabricated from certified grades suitable for residential construction

-

Protective coatings applied to suit internal exposure conditions

-

Finishes coordinated with the construction programme and architectural requirements

-

All materials selected to ensure strength, accuracy, and long-term performance

Standards & Compliance

All structural steelwork was designed, fabricated, and installed in accordance with relevant standards and statutory requirements, including:

-

BS EN 1090 – Execution of steel structures

-

UKCA compliance with full material certification and traceability

-

Structural design in accordance with BS EN 1993 (Eurocode 3)

-

Compliance with UK Building Regulations, including Approved Document A (Structure)

Project Outcome

Completed in 2025, the project demonstrates MK Metals Ltd’s capability to deliver high-quality structural steelwork for private residential developments, combining technical expertise, precision fabrication, and reliable on-site installation to support modern new-build housing.

🏘 Client: Datalec Precision Installations

🏛 Architect: N/A

📍 Location: London Docklands

📄 Contract: Purchase Order

💷 Project Value: £75,000

📅 Completion: Q3 2025

Project Summary: Data Centre – Structural Steelwork

MKMetals Ltd delivered the structural steelwork package for Battery Room 1, a new data centre facility in London Docklands. The works included the design, fabrication, supply, and installation of primary and secondary steelwork to support battery room infrastructure within a highly regulated, mission-critical environment.

The project demonstrates MK Metals Ltd’s capability to deliver technically demanding structural steelwork packages for data centre and critical infrastructure developments, meeting strict compliance, quality, and performance requirements.

🏘 Client: Private Residential Client

🏛 Architect: Private Architect

📍 Location: Exeter, Devon

📄 Contract: Direct Appointment

💷 Project Value: £25,000

📅 Completion: Q4 2025

Project Summary: Private Residential – Floating Staircase & Glass Balustrade

MK Metals Ltd designed, fabricated, and installed a bespoke floating staircase with frameless glass balustrades for a private residential home. Conceived as a central architectural feature, the staircase combines concealed structural steelwork with precision detailing to achieve a clean, minimalist floating appearance.

Working closely with the project team, the installation was carefully coordinated to ensure structural integrity, compliance, and seamless integration with the surrounding finishes. The completed staircase delivers a refined, contemporary focal point, demonstrating MK Metals Ltd’s expertise in high-end, bespoke residential metalwork.

🏘 Client: Private Residential Client

🏛 Architect: N/A

📍 Location: Branstaple, Devon

📄 Contract: Direct Appointment

💷 Project Value: £15,000

📅 Completion: Q4 2025

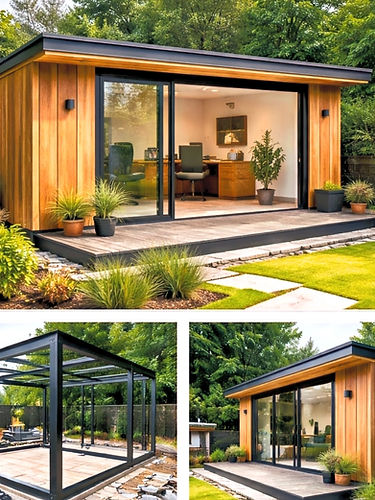

Project Summary: Private Residential – Bespoke Steel-Framed Garden Room

MKMetals Ltd designed, fabricated, and installed a bespoke steel-framed garden room to be used as a private home office. The structure combines a precision-engineered steel framework with natural timber cladding, creating a contemporary, durable workspace that sits comfortably within the surrounding garden setting.

The steel frame allowed for clean lines, open internal spans, and rapid installation, while the timber cladding provides warmth, visual appeal, and integration with the landscape. Delivered as a fully coordinated solution, the completed garden room offers a functional, high-quality workspace that demonstrates MK Metals Ltd’s capability in bespoke residential steel structures and hybrid material design.